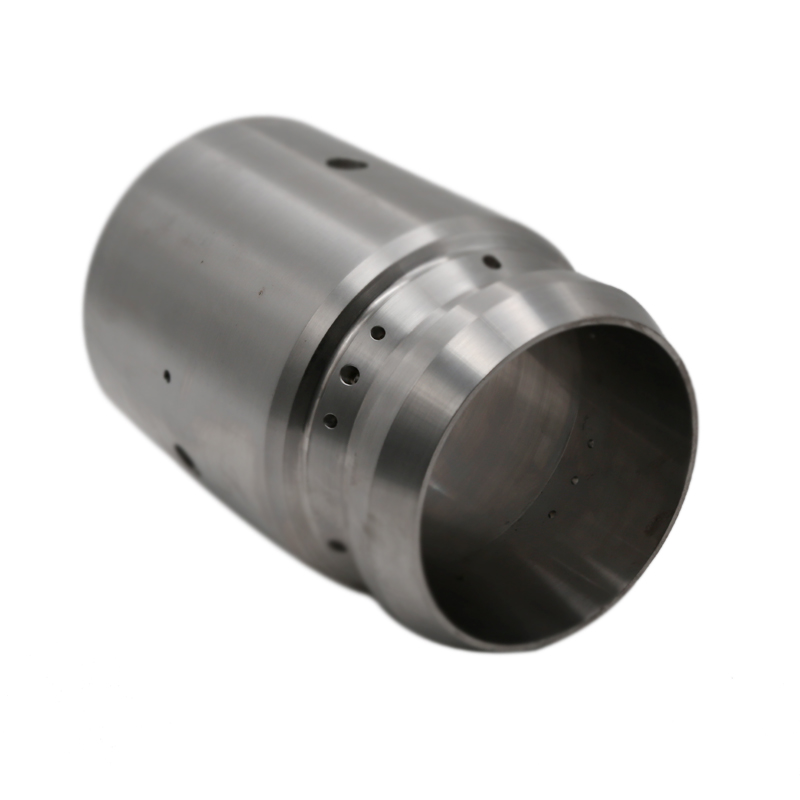

Inconel CNC akụkụ igwe kwụ ọtọ dị elu

Ngwa ndị dị:

Polycarbonate bụ polymer thermoplastic nke nwere otu carbonate jikọtara ọnụ iji mepụta molekul yinye ogologo. Ọ bụ plastik dị arọ, na-adịgide adịgide nke nwere ezigbo ngwa anya, ọkụ na ọkụ eletrik. Ọ na-eguzogide nke ukwuu na mmetụta, okpomọkụ na kemịkalụ, a na-ejikwa ya n'ọtụtụ ngwa ngwa, site na ngwaọrụ ahụike ruo na akụrụngwa ụgbọ ala. Ọ dị na ọkwa dị iche iche, ụdị na agba, a na-erekwa ya na mpempe akwụkwọ, mkpanaka na tubes.

Nkọwa nke Inconel Metals

1. Chemical mejupụtara: Inconel alloys a nwere nickel, chromium, ígwè, na ndị ọzọ ọcha dị ka molybdenum, cobalt, na titanium.

2, Mechanical Properties: Inconel alloys nwere elu ike, magburu onwe ductility, na ezi ike na ma ambient na elu okpomọkụ.

3, Corrosion Resistance: Inconel alloys nwere magburu onwe corrosion iguzogide a dịgasị iche iche nke gburugburu, gụnyere oxidizing na mbenata acids, nnu mmiri, na elu-okpomọkụ gas.

4, Okpomọkụ Performance: Inconel alloys nwere ike ịnọgide na-enwe ha n'ibu Njirimara na corrosion eguzogide na elu okpomọkụ ruo 2000 ° F (1093 ° C).

5, Weldability: Inconel alloys bụ weldable iji ot ịgbado ọkụ usoro, ma ụfọdụ akara ule nwere ike ịchọ preheating na post-weld okpomọkụ ọgwụgwọ ịnọgide na-enwe ha Njirimara.

6, akara ule: E nwere dị iche iche akara ule nke Inconel alloys dị, gụnyere Inconel 600, Inconel 625, Inconel 718, na Inconel X-750, onye ọ bụla na kpọmkwem chemical mejupụtara na Njirimara.

Nkọwapụta Ụlọ ọrụ

LAIRUN tọrọ ntọala na 2013, anyị bụ onye na-emepụta akụkụ CNC na-arụ ọrụ nke ọma, raara onwe ya nye inye akụkụ ziri ezi dị elu maka ụlọ ọrụ dị iche iche. Anyị nwere ihe dị ka ndị ọrụ 80 nwere ahụmịhe afọ na otu ndị ọkachamara nwere nkà, anyị nwere nka na akụrụngwa ọgbara ọhụrụ dị mkpa iji mepụta ihe ndị dị mgbagwoju anya na-enweghị oke na nkwụsi ike.