Kedu ụdị ihe pụrụ iche ga-eji na mmanụ & Gas CNC machined?

Akụkụ CNC ejiri rụọ ọrụ mmanụ na gas chọrọ ihe pụrụ iche nke nwere ike iguzogide nrụgide dị elu, okpomọkụ dị elu, na gburugburu gburugburu. Nke a bụ ụfọdụ ihe ndị pụrụ iche a na-ejikarị na mmanụ na gas CNC arụnyere yana koodu akụrụngwa ha:

Mgbe ị na-ahọrọ ihe maka mmanụ na gas na-emepụta akụkụ CNC, ọ dị mkpa iji tụlee ihe ngwa ngwa chọrọ, dị ka nrụgide, okpomọkụ, na nkwụsị nke corrosion. A ghaghị ịhọrọ nke ọma nke ọma iji hụ na akụkụ ahụ nwere ike iguzogide ibu ndị a na-atụ anya ya na ọnọdụ gburugburu ebe obibi ma nye ọrụ a pụrụ ịdabere na ya n'elu ndụ ọrụ a chọrọ.

| Ihe Nkịtị Mmanụ | Koodu ihe eji eme mmanụ |

| Nickel Alloy | Adị 925,INCONEL 718(120,125,150,160 KSI),NITRONIC 50HS,MONEL K500 |

| Igwe anaghị agba nchara | 9CR,13CR, SUPER 13CR,410SSTANN,15-5PH H1025,17-4PH(H900/H1025/H1075/H1150) |

| Igwe anaghị agba nchara magnetik | 15-15LC,P530,Datalloy 2 |

| Alloy Steel | S-7,8620,SAE 5210,4140,4145H MOD,4330V,4340 |

| Alloy ọla kọpa | AMPC 45, TOUGHMET, Brass C36000, Brass C26000, BeCu C17200, C17300 |

| Titanium Alloy | CP TITANIUM GR.4,Ti-6AI-4V, |

| Cobalt-base Alloys | STELLITE 6,MP35N |

Kedu ụdị ihe pụrụ iche ga-eji na mmanụ & Gas CNC machined?

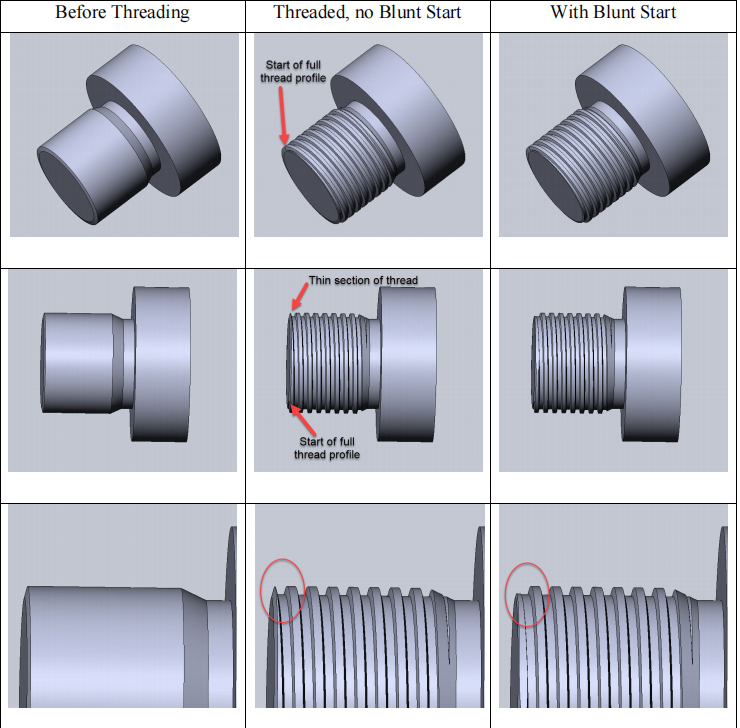

Ekwesịrị ịmebe eriri pụrụ iche nke ejiri mmanụ na gas CNC rụọ ọrụ iji gboo ihe achọrọ ngwa ngwa, dị ka nrụgide dị elu, oke okpomọkụ, na ọnọdụ gburugburu ebe obibi siri ike. Eriri ndị a na-ejikarị eme ihe na ụlọ ọrụ mmanụ na gas gụnyere:

Megharịa nzaghachi

Mgbe ị na-ahọrọ eriri maka mmanụ na gas nke CNC na-emepụta ihe, ọ dị mkpa ka ị tụlee ihe ngwa ngwa chọrọ ma họrọ eri nke nwere ike iguzogide ibu ndị a tụrụ anya na ọnọdụ gburugburu ebe obibi. Ọ dịkwa mkpa iji hụ na a na-emepụta eri ahụ na ụkpụrụ kwesịrị ekwesị na nkọwa iji hụ na ndakọrịta na ihe ndị ọzọ dị na usoro ahụ.

Lee ụfọdụ eri pụrụ iche maka ntụnye aka:

| Ụdị eriri mmanụ | Ọgwụgwọ ihu ihu pụrụiche mmanụ |

| Eriri UNRC | Vacuum eletrọn beam ịgbado ọkụ |

| Eriri UNRF | Ọkụ na-efesa (HOVF) nickel tungsten carbide |

| Eriri TC | Ọla kọpa |

| Eriri API | HVAF (Mkpụrụ ọkụ ikuku dị elu) |

| Eriri Spiralock | HVOF (Oxy-Fuel Ọsọ Ọsọ) |

| Eriri Square |

|

| eriri Buttress |

|

| Eriri Buttress Pụrụ Iche |

|

| Eriri OTIS SLB |

|

| Ọnụ ego NPT |

|

| Rp(PS) eriri |

|

| RC (PT) eriri |

Kedu ụdị ọgwụgwọ elu pụrụ iche ga-eji na mmanụ & Gas CNC machined?

Ngwọta dị n'elu nke akụkụ CNC igwe bụ akụkụ dị mkpa nke ịhụ na ọrụ ha, ịdịte aka, na ogologo ndụ ha na ọnọdụ ọjọọ nke ụlọ ọrụ mmanụ na gas. Enwere ọtụtụ ụdị ọgwụgwọ elu nke a na-ejikarị na ụlọ ọrụ a, gụnyere:

Ọ dị mkpa ịhọrọ ọgwụgwọ elu kwesịrị ekwesị dabere na ngwa ngwa na ọnọdụ ọrụ nke akụkụ CNC na-arụ ọrụ na mmanụ na gas. Nke a ga-eme ka akụkụ ndị ahụ nwee ike iguzogide ọnọdụ ndị siri ike ma rụọ ọrụ ha bu n'obi rụọ ọrụ nke ọma na nke ọma.

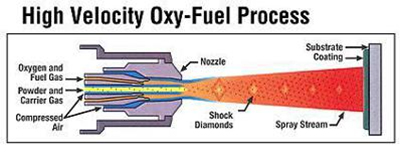

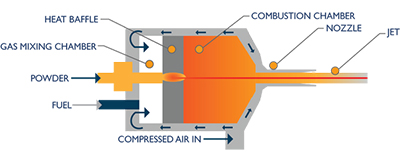

HVAF (mmanụ ikuku dị elu) &HVOF (mmanụ ọkụ oxygen dị elu)

HVAF (Elu-Velocity Air Fuel) na HVOF (High-Velocity Oxygen Fuel) bụ teknụzụ mkpuchi elu abụọ dị elu nke a na-ejikarị na ụlọ ọrụ mmanụ na gas. Usoro ndị a na-agụnye ikpo ọkụ ihe ntụ ntụ ma mee ka ọ dịkwuo elu tupu ịdoba ya n'elu akụkụ ahụ arụpụtara. Ogo dị elu nke ụmụ irighiri ihe ntụ ntụ na-eduga na mkpuchi dị oke ma na-ejidesi ike nke na-enye nguzogide dị elu nke iyi, mbuze, na corrosion.

HVOF

HVAF

Enwere ike iji mkpuchi HVAF na HVOF mee ka arụmọrụ na ndụ nke akụkụ CNC na-arụ ọrụ na mmanụ na gas. Ụfọdụ uru nke mkpuchi HVAF na HVOF gụnyere:

1.Nguzogide corrosion: mkpuchi HVAF na HVOF nwere ike inye ezigbo nguzogide corrosion na akụkụ igwe eji arụ ọrụ na gburugburu ebe siri ike nke ụlọ ọrụ mmanụ na gas. Ihe mkpuchi ndị a nwere ike ichebe elu nke akụkụ ahụ site na ikpughe na kemịkalụ na-emebi emebi, okpomọkụ dị elu, na nrụgide dị elu.

2.Nguzogide iyi: mkpuchi mkpuchi HVAF na HVOF nwere ike inye ihe mgbochi dị elu karịa akụkụ igwe eji arụ ọrụ mmanụ na gas. Ihe mkpuchi ndị a nwere ike ichebe elu nke akụkụ ahụ site na iyi n'ihi abrasion, mmetụta, na mbuze.

3.Mmanya mmanye: mkpuchi HVAF na HVOF nwere ike imezi mmanu nke akụkụ igwe eji arụ ọrụ mmanụ na gas. Ihe mkpuchi ndị a nwere ike ibelata esemokwu n'etiti akụkụ ndị na-akpụ akpụ, nke nwere ike ime ka arụ ọrụ dị mma ma belata iyi.

4.Nguzogide okpomọkụ: mkpuchi HVAF na HVOF nwere ike inye ezigbo nguzogide okpomọkụ nke akụkụ igwe eji arụ ọrụ mmanụ na gas. Ihe mkpuchi ndị a nwere ike ichebe akụkụ ahụ site na ujo ọkụ na ịgba ígwè, nke nwere ike ime ka ọkpụkpụ na ọdịda.

5.Na nchịkọta, mkpuchi HVAF na HVOF bụ teknụzụ mkpuchi elu dị elu nke nwere ike inye nchebe dị elu na akụkụ CNC ejiri rụọ ọrụ mmanụ na gas. Ihe mkpuchi ndị a nwere ike imeziwanye arụmọrụ, ịdịte aka, na ndụ nke akụkụ ahụ, na-eduga n'ịrụ ọrụ nke ọma ma belata ụgwọ ọrụ.