Ịtụ CNC a chịkọtara

Ndị otu a na-ejikọ aka

Aluminom 6061-t6|3.3211 |65028 |Almg1sicu: Uru a bụ otu n'ime almuys ndị a na-ahụkarị nke aluminom. A na-ejikarị ya na ọtụtụ ụlọ ọrụ yana ebumnuche General Equire. Ọ na-enye ezigbo Waldibly, nguzogide na nguzogide na igwe. Ọ bụ otu ihe akara ule kachasị mkpa maka iwe, mana akụrụngwa ya na-eme ka ọ dị mma maka ọtụtụ ndị ọzọ ngwa.

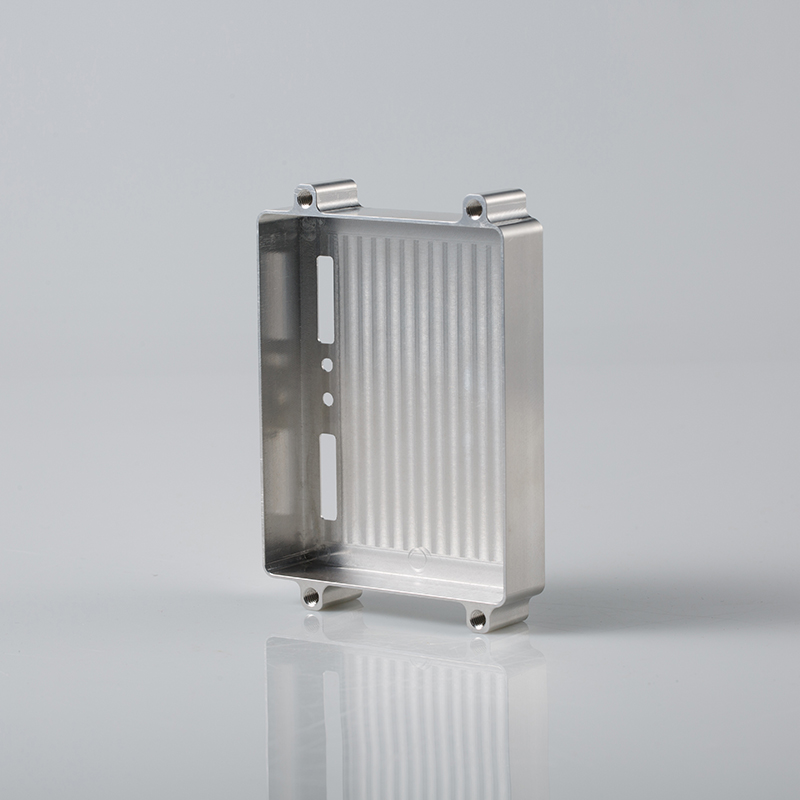

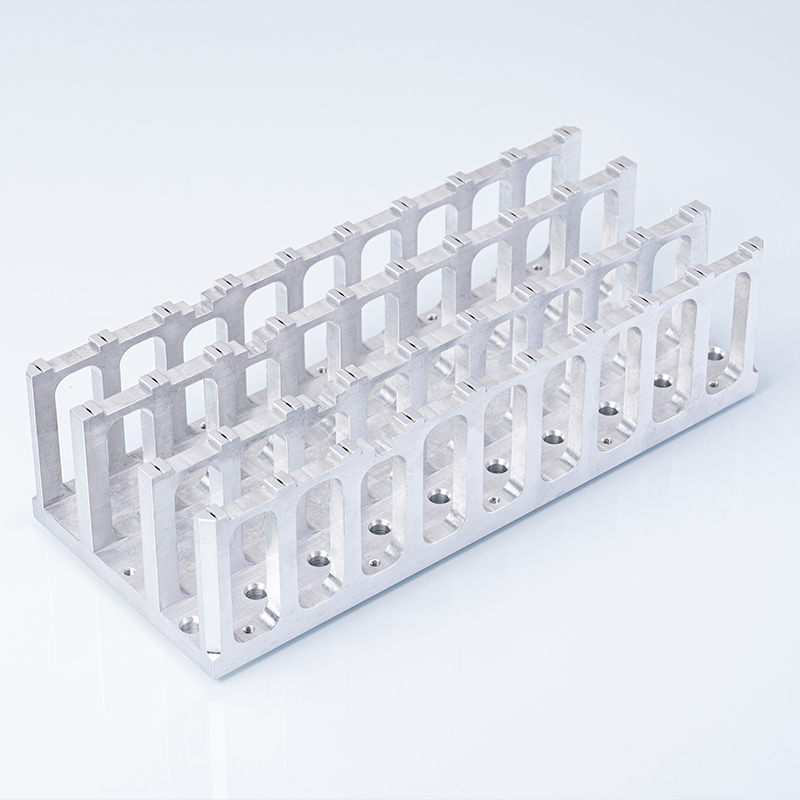

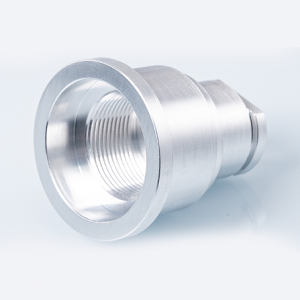

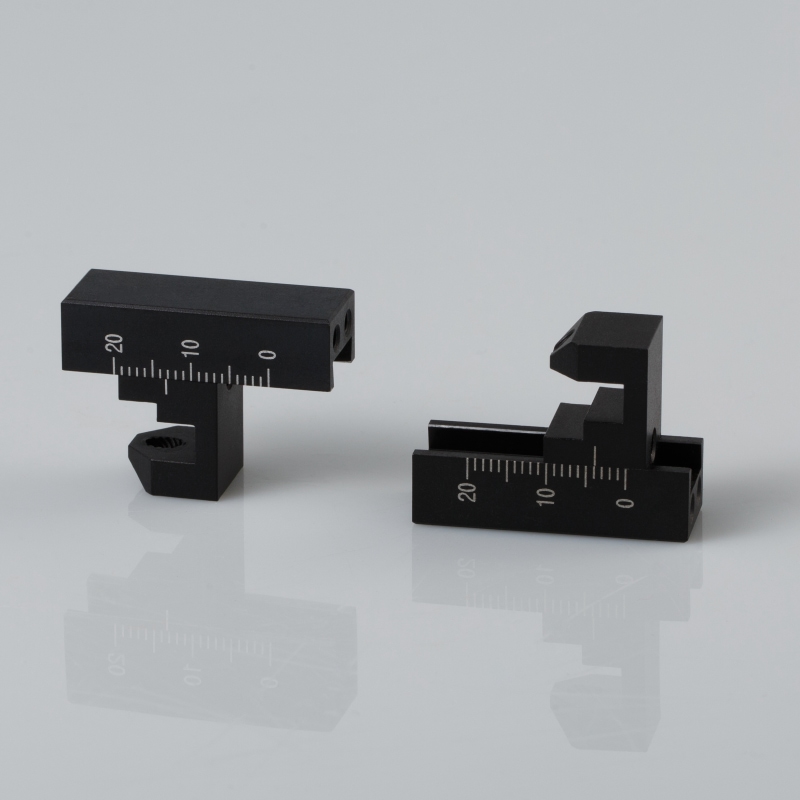

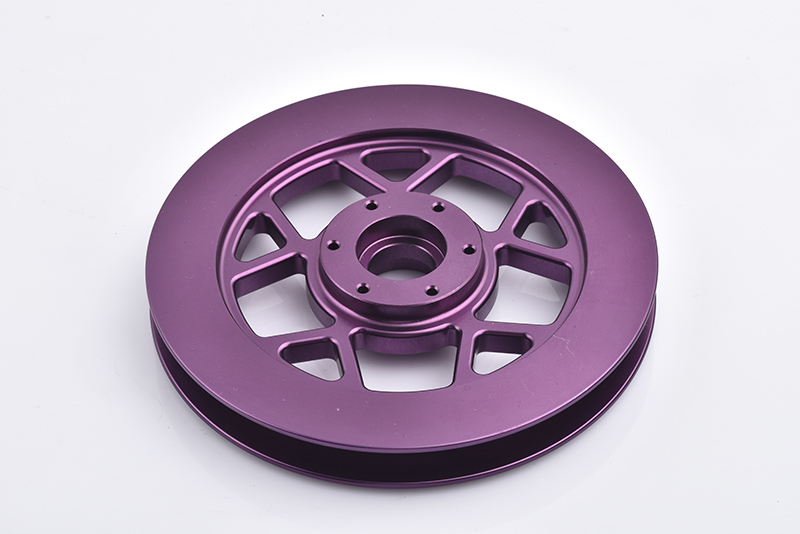

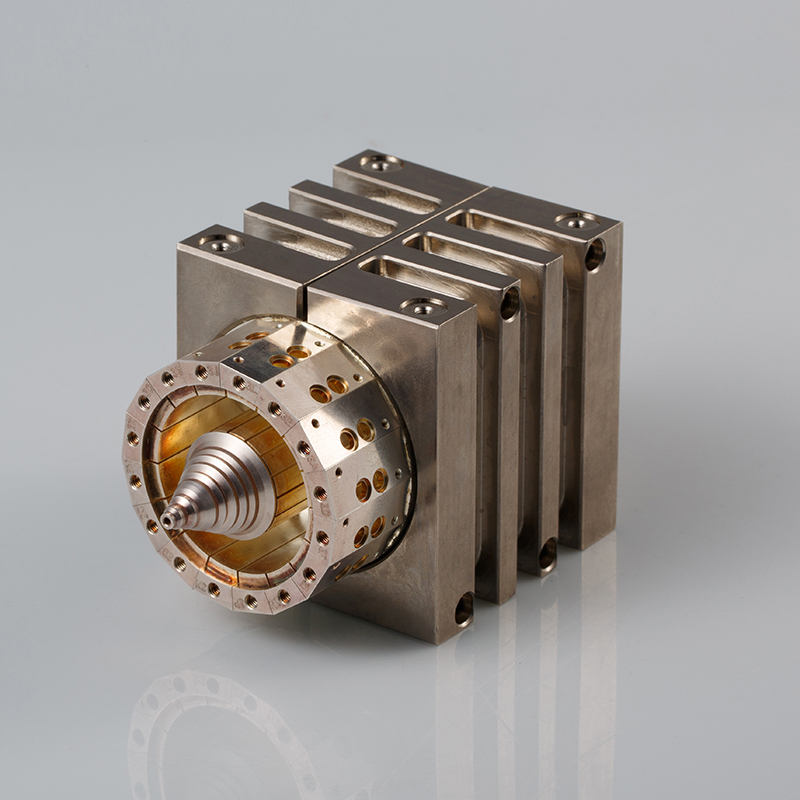

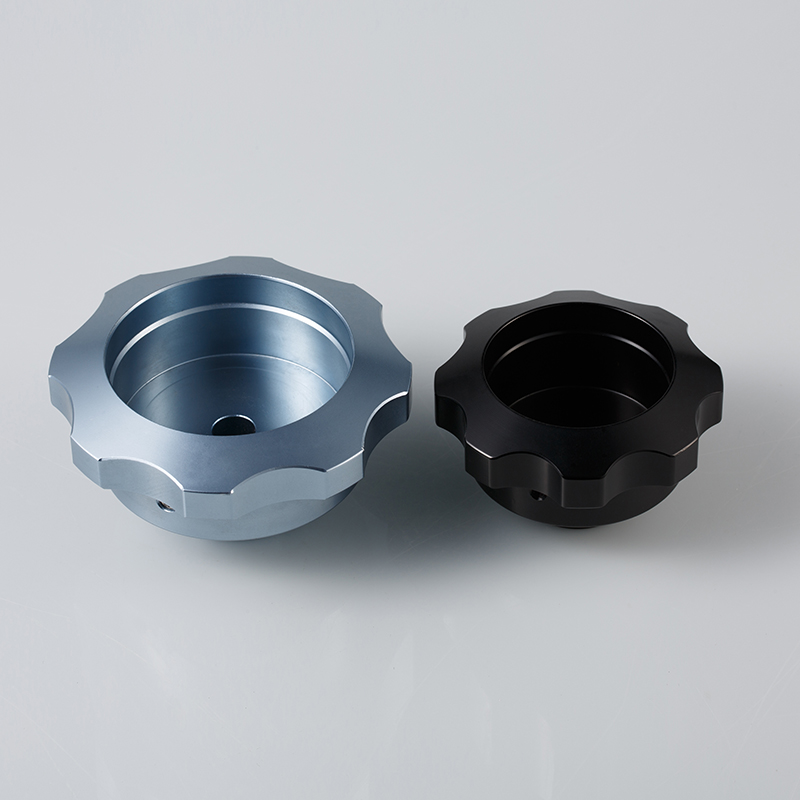

Imepụta akụkụ nke akụkụ aluminom

CNC machining bụ otu n'ime usoro a ma ama maka usoro aluminom. Usoro a gụnyere iji ngwa eji kọmputa na-achịkwa kọmputa na iji belata, ọdịdị, ma na-akpọkọta aluminom na akụkụ achọrọ. A maara igwe CNC maka izi ezi ya, iweghachi ozi ọma, na ọkwa dị elu. A na-ejikarị usoro a na-emepụta akụkụ ya na geometries geometries dị mgbagwoju anya na nnabata.

Aluminom 6082|3.2315|64430 | Alsi1mgmn:6082 bụ amaara maka nguzogide ya nke ọma, ike dị elu - nke kachasị elu nke 6000 usoro alloys ọ ga - eji dochie anya 3061 n'ọtụtụ ngwa. Ọ bụ ihe a na-ahụkarị maka usoro, n'agbanyeghi na o siri ike iwepụta mgbidi dị mkpa.

Aluminom 5083-h111|3.3547|54300 |Alcg4.5mn0.7:5083 alloy alloy bụ ezigbo nhọrọ maka mpaghara dị egwu n'ihi ya na-eguzosi ike mmiri, kemịkal, ọgụ. Ọ dịla elu ike na ịdị mma corrosion. Alloey a na-apụta n'ihi na ọ bụghị ikere site na ọgwụgwọ ọkụ. N'ihi ike ya dị elu, ọ nwere obere ihe dị iche iche nke enwere ike igwe, mana ọ nwere iwe iwe zuru oke.

Aluminom 5052|Ew aw-5052|3.3523| Hilgg2,5: Aluminium 5052 alloy dị elu magnesium alloys na dị ka usoro 5000 niile nwere ike dị elu. Enwere ike isi ya sie ike site na oge oyi na-arụ ọrụ, yabụ na-eme ka usoro "H". Agbanyeghị, ọ bụghị a na-agwọ ya ọkụ. O nwere ezigbo corrosion iguzogide nnuku mmiri, ọkachasị na mmiri nnu.

Aluminom mic6: Mig-6 bụ efere aluminom nke bụ ngwakọta nke ọla dị iche iche. Ọ na-enye ezi ozi ọma na mma. A na-emepụta site na nkedo 6 nke na-ebute ihe na-akpata nsogbu. Ọzọkwa, ọ bụ ibu dị mfe, na-ehicha ma na-enweghị nsogbu, mmerụ na ndagide.